Innovative Solutions from a Transformer Oil Regeneration Plant

Innovative Solutions from a Transformer Oil Regeneration Plant

Blog Article

Why Regenerated Transformer Oil Is Essential for Reliable Power Systems

The vital role of regenerated transformer oil in ensuring the dependability of power systems can not be overemphasized. By restoring the oil's intrinsic chemical and physical properties, the regrowth procedure considerably improves its dielectric strength and thermal performance.

Relevance of Transformer Oil

Transformer oil plays a vital duty in the reliable procedure of electric transformers. This customized oil serves multiple functions, primarily as an insulator and coolant, making certain the secure and reliable efficiency of transformer systems. Its dielectric residential or commercial properties prevent electrical discharges, hence securing the integrity of transformer elements. By supplying thermal conductivity, transformer oil dissipates heat generated during electric procedure, which is vital for maintaining optimum operating temperatures and extending the life-span of the devices.

Furthermore, transformer oil acts as a barrier versus wetness and air, which can cause oxidation and destruction of transformer products. The visibility of pollutants in the oil can substantially impair its shielding buildings, causing functional ineffectiveness and potential equipment failure. Regular surveillance and upkeep of transformer oil are therefore crucial to making sure the continued effectiveness of transformers.

The high quality and make-up of transformer oil are vital, as they directly impact the reliability and performance of the electrical systems in which they run. Recognizing the value of transformer oil is important for energies and markets reliant on robust power infrastructure, stressing the need for reliable monitoring and regrowth procedures to preserve oil honesty with time.

Advantages of Regeneration Refine

Furthermore, the regeneration process alleviates the destruction of oil, which can result in raised oxidation and acid formation. This not only enhances the integrity of the oil but likewise lowers the threat of transformer failures due to insulation break down. The enhanced high quality of regrowed oil enables transformers to run at optimum degrees, inevitably resulting in enhanced power efficiency and decreased operational costs.

Furthermore, the regrowth process contributes to preserving the general wellness of the power system. Transformers can run much longer without the demand for oil substitute, therefore reducing downtime and maintenance efforts. In summary, the regeneration process supplies considerable benefits by enhancing the longevity and efficiency of transformer oil, guaranteeing that power systems operate reliably and successfully over time.

Ecological Effect and Sustainability

The regrowth process of transformer oil substantially reduces environmental issues associated with oil disposal and waste management. Conventional disposal techniques for utilized transformer oil pose check my site significant dangers, including soil contamination and water contamination. By regrowing oil, these risks are significantly decreased, as the process recycles existing sources rather of adding to squander buildup.

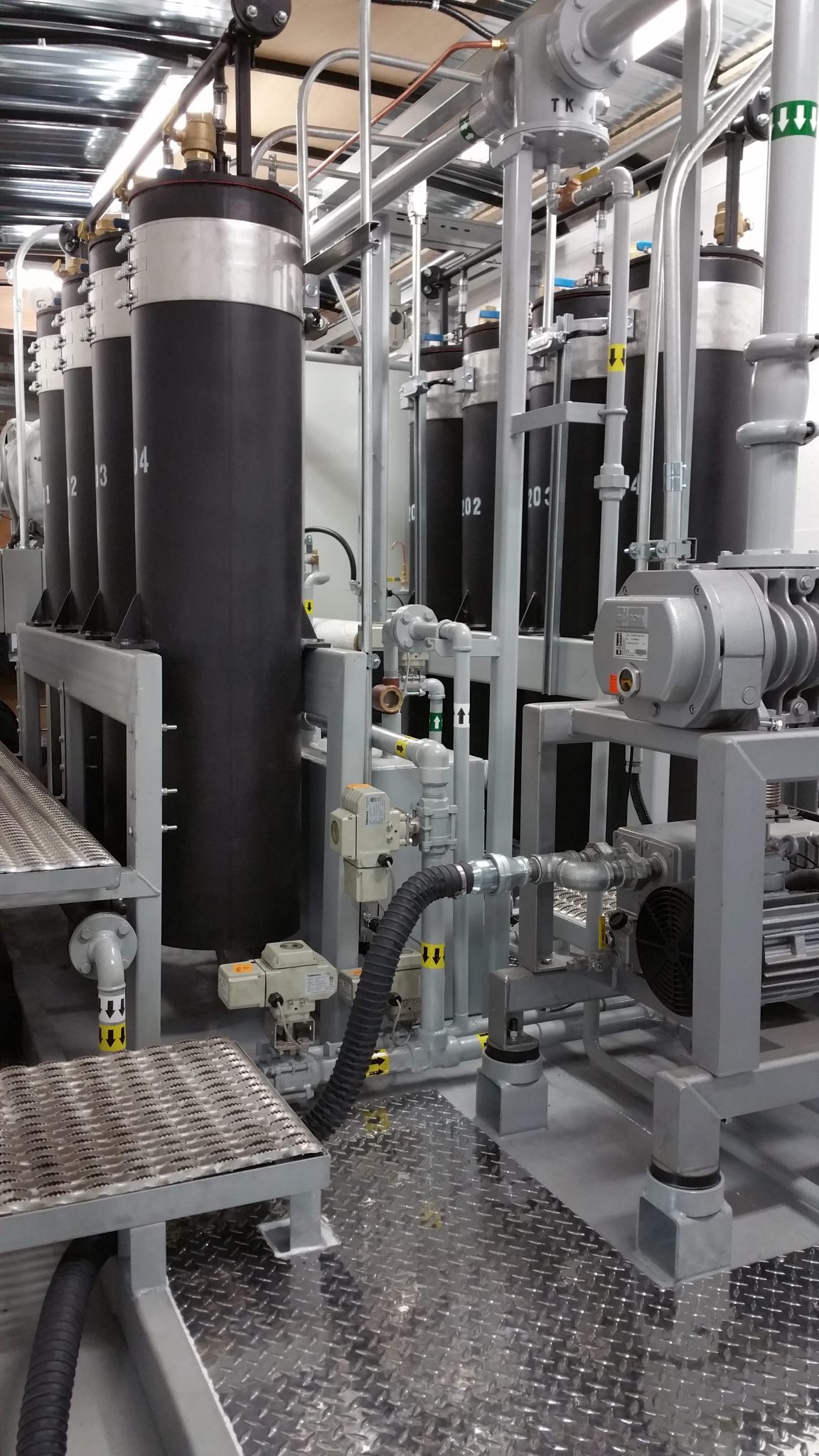

Furthermore, regenerated transformer oil can be reused in different applications, which promotes a round economic climate. This not just decreases the requirement for virgin oil extraction-- a process that can be eco destructive-- however also saves natural resources. The regrowth process itself uses sophisticated filtration and purification strategies that eliminate dangerous impurities, making certain that the end product meets or surpasses industry requirements for performance and safety.

Enhancing Transformer Efficiency

Substantial improvements in transformer efficiency can be attained through the usage of regenerated transformer oil. This oil, produced via innovative filtration procedures, significantly enhances the electric insulation residential properties of transformers. By eliminating contaminations and pollutants that typically endanger efficiency, regenerated oil guarantees exceptional dielectric stamina, decreasing the threat of electric failings.

In addition, regenerated transformer oil exhibits boosted thermal conductivity, which assists in effective warm dissipation. This particular is essential for maintaining optimal operating temperatures, thereby extending the life expectancy of transformers and reducing the possibility of overheating - Transformer Oil Regeneration. Enhanced thermal administration also adds to the overall integrity of power systems

In addition, the chemical security of regrowed oil avoids the development of destructive acids and sludge, which can negatively impact transformer components. By maintaining a cleaner interior setting, this oil lessens maintenance demands and expands service intervals.

Cost-Effectiveness and Performance

In regards to cost-effectiveness and efficiency, restored transformer oil presents a compelling alternative to conventional oils. The regrowth procedure not only removes contaminants yet also recovers the oil's initial buildings, prolonging its functional life-span. This durability converts into reduced regularity of oil substitute, thus decreasing operational expenses over time.

In addition, making visite site use of restored oil can dramatically decrease power losses connected with ineffective insulating liquids. Our site Its exceptional dielectric homes ensure ideal performance, improving the integrity of power systems. Therefore, businesses take advantage of reduced maintenance prices and decreased downtime, promoting an extra effective operational atmosphere.

Final Thought

To conclude, the regeneration of transformer oil plays a vital duty in ensuring the integrity and effectiveness of power systems. By bring back the crucial chemical and physical residential or commercial properties of the oil, this procedure enhances dielectric stamina and thermal conductivity, inevitably lowering the threat of insulation breakdown. The ecological benefits linked with recycling resources add to sustainability initiatives, while cost-effectiveness and boosted performance highlight the necessity of utilizing regenerated transformer oil in modern electric facilities.

Transformer oil plays a crucial role in the efficient procedure of electrical transformers. Routine tracking and maintenance of transformer oil are for that reason crucial to making sure the proceeded efficiency of transformers.

The regeneration procedure of transformer oil significantly reduces environmental concerns linked with oil disposal and waste monitoring. By extending the lifecycle of transformer oil, the energy and resources generally eaten in creating new oil are significantly decreased.Substantial enhancements in transformer performance can be attained through the usage of regenerated transformer oil.

Report this page